Petrochemical Lining

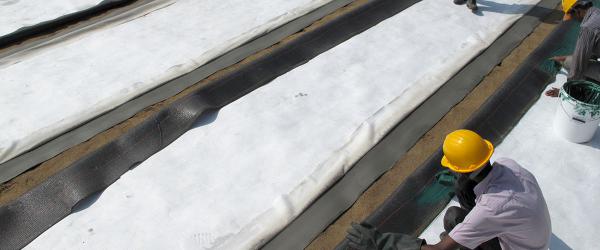

Refineries and Tank Terminals require secure bunds, concrete and earth bunds provide the secondary containment in the event of a spill. Many bunds, often those built years ago, had no impermeable layer within them which would prevent seepage of any spill of oil into the ground. RAWMAT® HDB provides an impermeable liner which can be retrospectively installed into these bunds. RAWMAT® HDB's prehydration of the bentonite central core means that it can be installed onto a formation which has been subject to a hydrocarbon spillage, and the costly removal of contaminated material prior to the installation of the membrane is not necessary when RAWMAT® HDB is used. Furthermore, contaminated material which normally would have been removed from within the existing formation, at high cost, can be used within the bund to confine the membrane. Rawmat® provides a safe and cost effective solution to the provision or replacement of the liners below fuel storage tanks. Rawmat® HDB is equally suited as the secondary containment liner to the bund floors and tank bases of new construction Oil sites and has been used successfully on projects across the world with most of the major oil companies.

Tank farms (both concrete and earth) are readily and securely bunded with RAWMAT® HDB. RAWMAT® HDB's prehydration means that it can be installed into contaminated ground without fear of breakdown of the bentonite core. Its flexibility to fix easily to existing concrete structures makes it the secondary liner of choice of many of the worlds oil refining and storage companies.